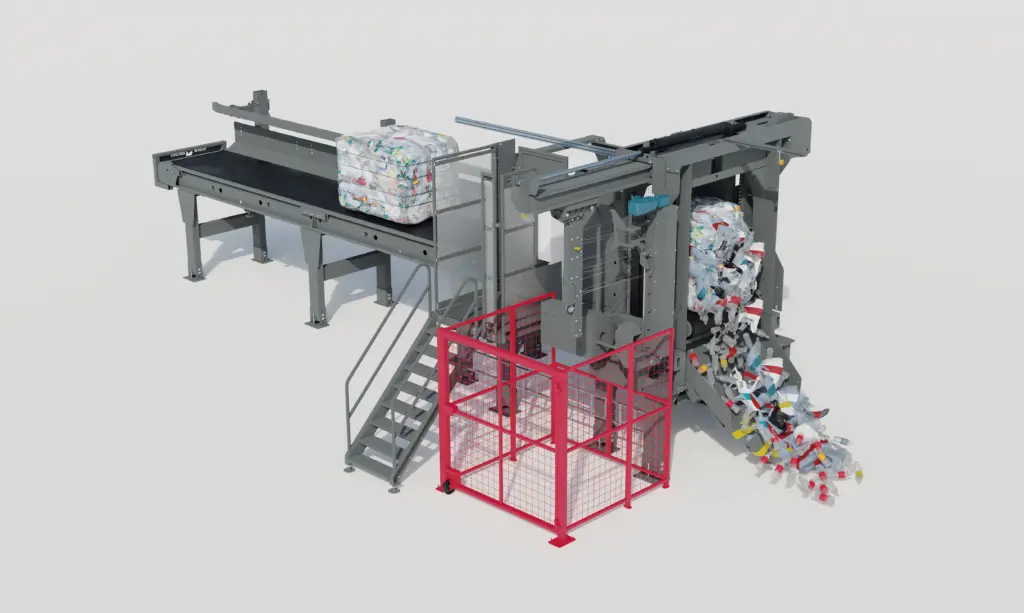

Manual Dewiring and Safety Risks

Plastic bales are tightly compressed and wired, more often cross-wired, making manual cutting dangerous and time-consuming. Operators face risks from sharp wires and heavy handling.

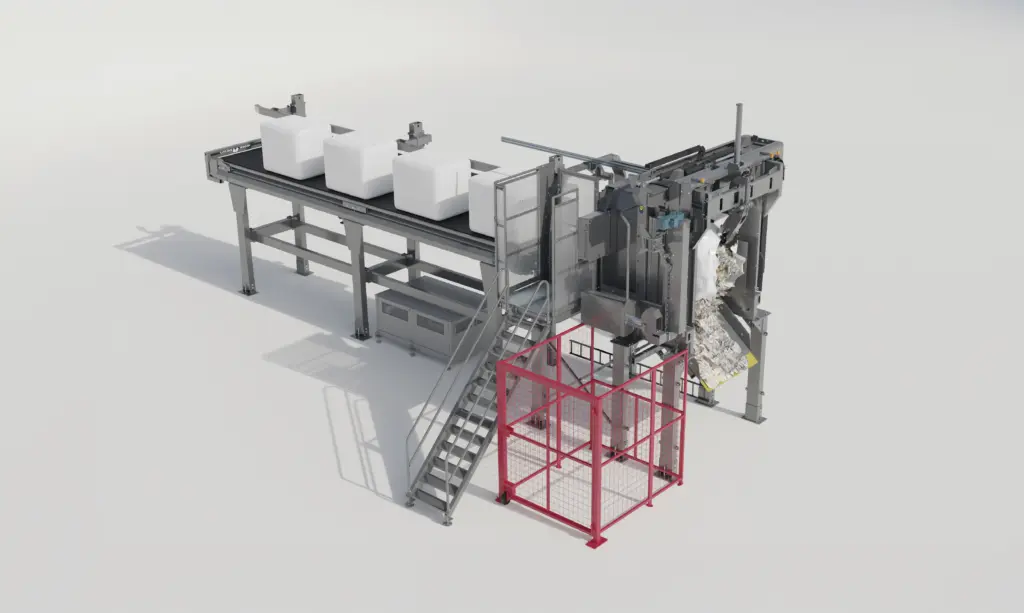

Inconsistent Material Flow

Manual bale opening leads to uneven feed into recycling lines. This causes downtime and reduced process efficiency. Variable bale composition (film, PET/HDPE/LDPE) demand flexible automation as well.

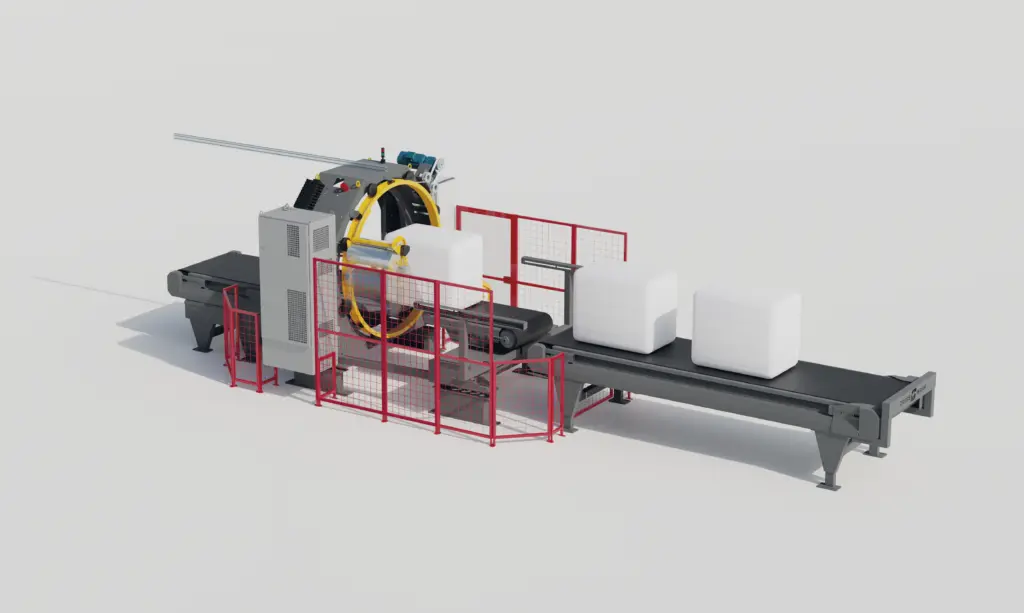

High Labor and Operating Costs

Manual handling increases labor needs, slows down production, and raises costs. Plants under pressure to process more with less need automation.

Equipment Wear and Downtime

Loose wires entering shredders, extruders, or washing lines cause equipment jams, excessive wear, and costly unplanned downtime. There can be also contamination and littering risks during infeed and preparation.

Sustainability Demands

The industry faces pressure to improve safety, efficiency, and sustainability. Wire waste must be managed, and operations optimized for recycling goals.