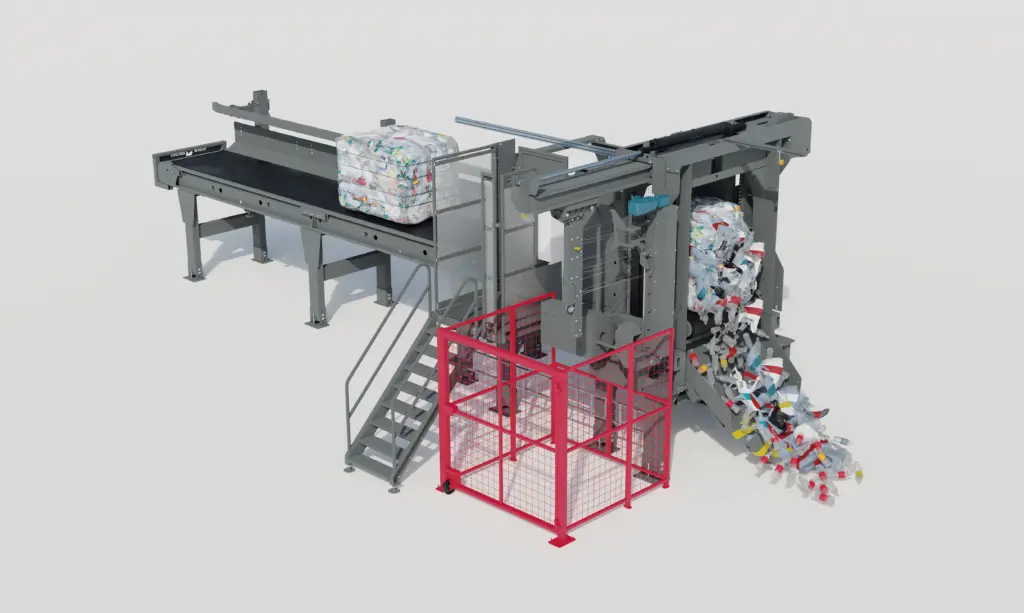

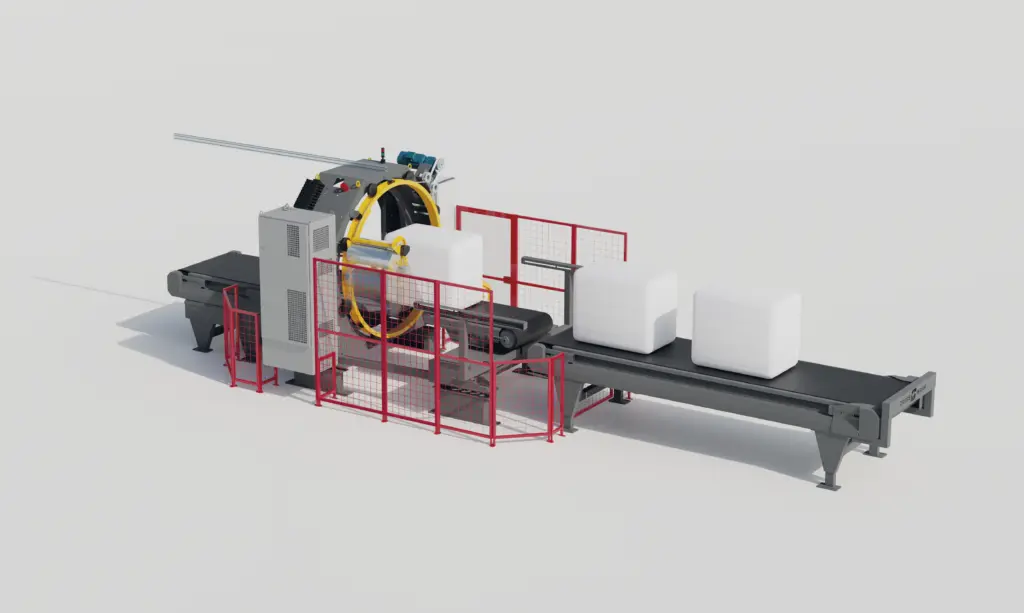

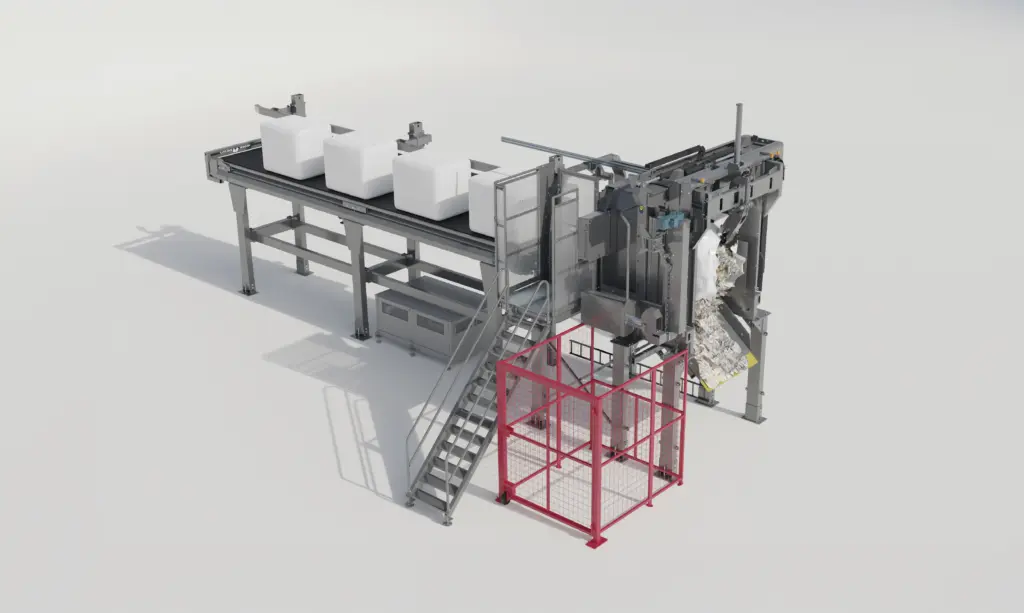

The Weighing from Cross Wrap adds automation to your bale or package handling. Integrated directly into the Cross Wrap’s machine, this upgrade acts as an automatic scale – accurately measuring each bale or package as it moves through the process. It delivers critical weight data for individual items and cumulative production, enhancing traceability, logistics, and operational visibility.

How it works?

Load cells are installed between the conveyor and frame to enable weighing feature. As each bale or package travels over the conveyor, the system records its weight and the data can be uploaded to your facility’s internal archive or monitoring system. With full integration into the control system of the machine, the weighing process happens automatically without interrupting throughput.

Benefits – Why choose Cleaning Conveyors?

Accurate in-line weighing

Each bale or package is weighed as part of the production line, no separate offline scale needed.

Real-time data & traceability

Get individual weights plus cumulative totals (shift, day, week) to monitor production performance.

Reduced forklift traffic

Eliminates the need to move bales/packages for weighing, lowering material handling and improving safety.

Better load optimisation

With accurate weights you can optimise truck loads, reduce over- or under-loading and save logistics cost.

Easy integration

Works with Cross Wrap machines and integrates into the control system.

Operational visibility

Weight data provides insight into capacity, throughput, performance trends and helps identify inefficiencies.