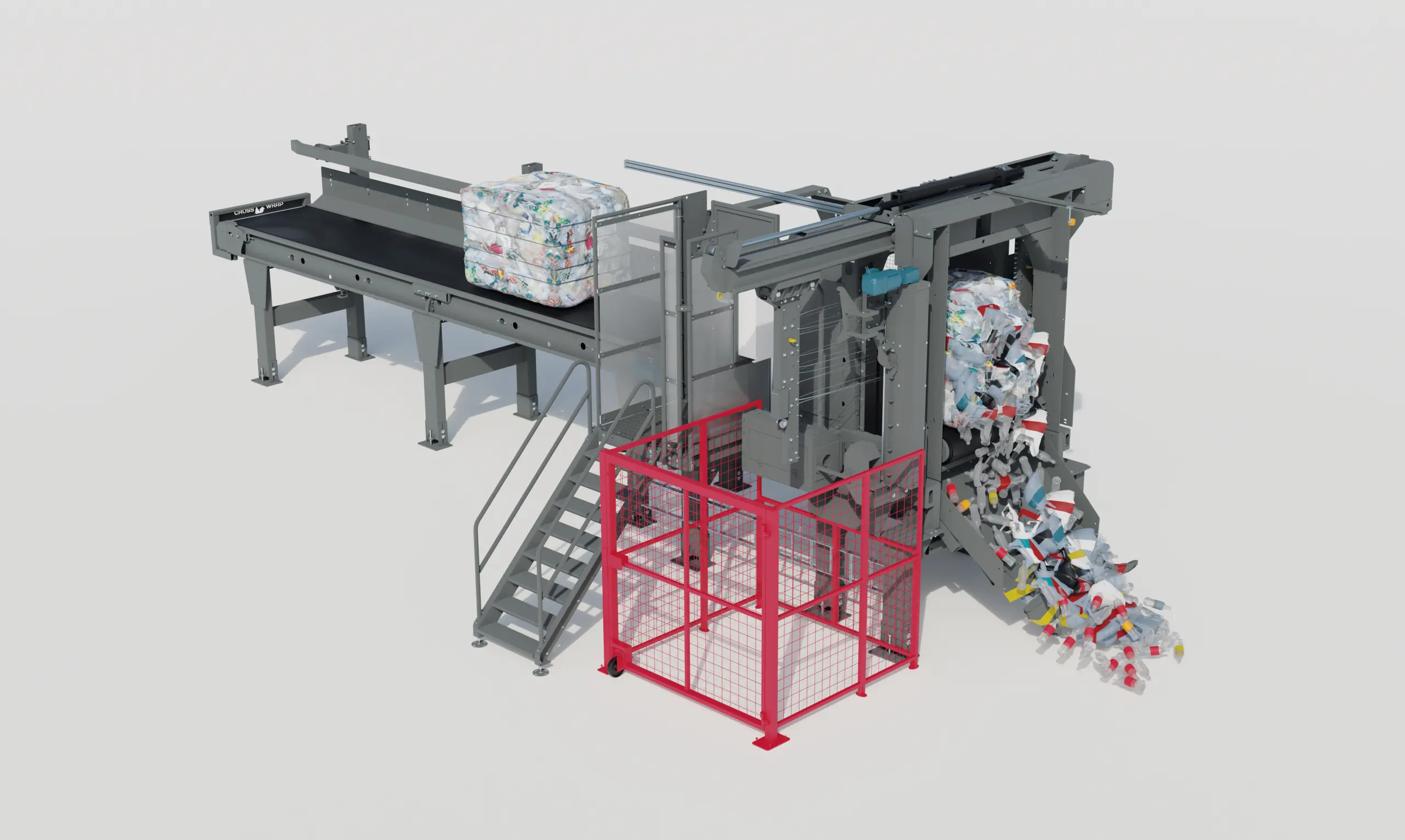

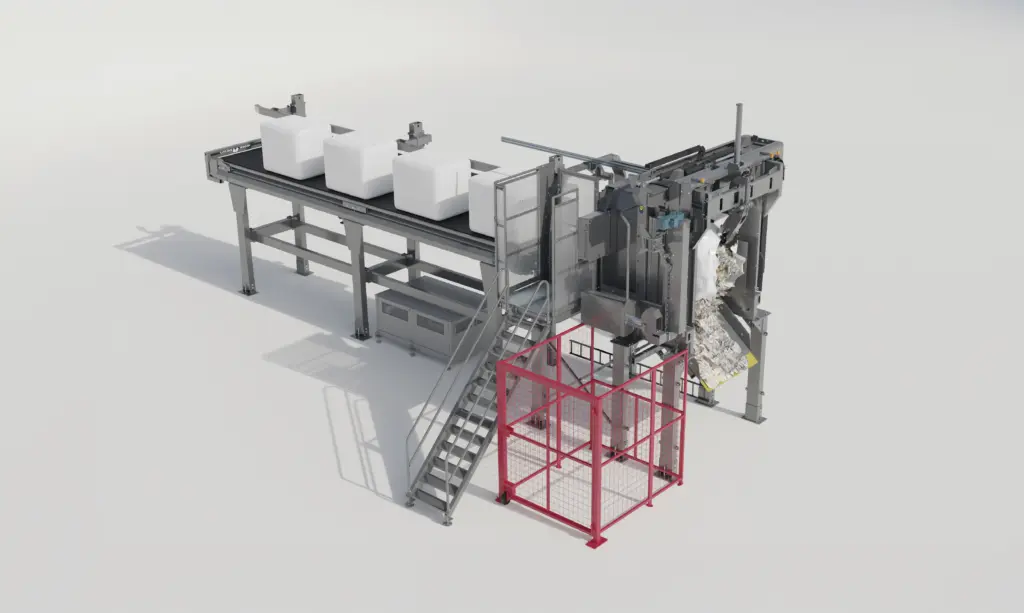

The Cross Wrap Magnetic Conveyor is a durable and fully integrated solution designed to work seamlessly with the Wire Shredder system. This product combination, including both the magnetic conveyor and its supporting stand, ensures reliable separation of ferromagnetic metal wires from shredded material flow, enhancing process efficiency and purity of the output.

The system delivers over 99% weight-based separation efficiency, helping operators achieve clean material streams and optimized recycling performance.

How it works?

The Magnetic Conveyor is installed directly after the wire shredder in the material flow. As shredded material moves along the strong rubber belt with 50 mm cleats, the integrated magnetic conveyor automatically lifts and separates ferromagnetic metal components from the shredded material.

The adjustable conveyor height allows fine-tuning for optimal separation results, while the Cross Wrap control system ensures the conveyor operates only when the shredder is feeding material, and reduces energy consumption and extends component lifespan.

Benefits – Why choose Magnetic Conveyor?

High separation efficiency

Over 99 % of ferromagnetic metal is removed from shredded material flow.

Energy-efficient operation

Conveyor runs only when the shredder is feeding material.

Adjustable height

Enables optimal magnetic field positioning for different material types.

Strong and reliable design

Durable rubber belt ensures continuous and effective conveying.

Seamless integration

Designed to work perfectly with Cross Wrap’s Wire Shredder and conveyor systems.

Reduced wear and downtime

Controlled operation and robust construction extend service life.

Turnkey package

Delivered as a combined unit (magnetic conveyor + stand) for easy installation and consistent performance.