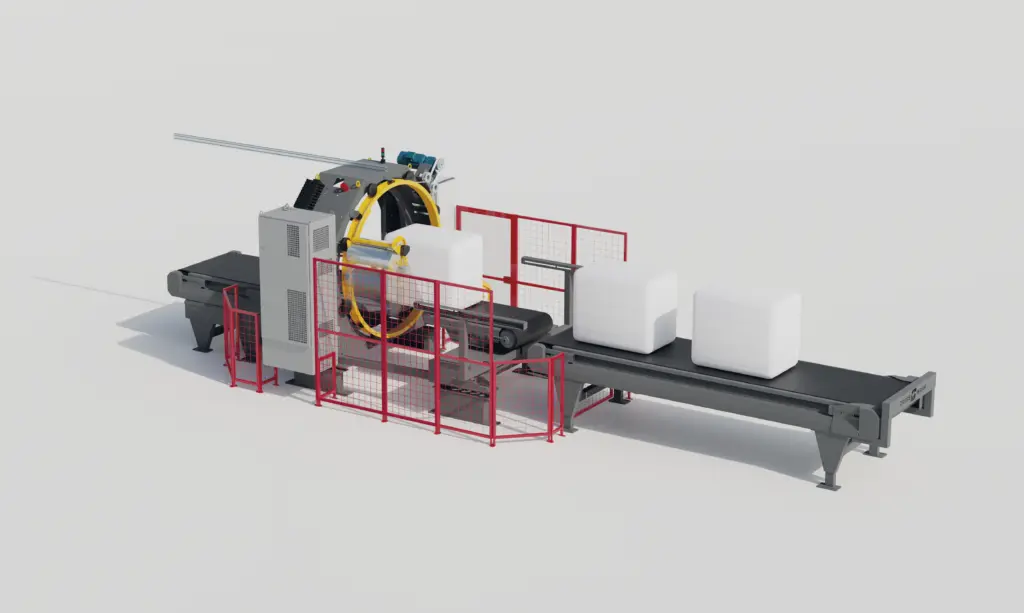

The Cross Wrap Cleaning Conveyor is designed to complement the precision and reliability of Cross Wrap bale handling lines. While our technology ensures exceptionally clean and accurate bale wrapping and dewiring, the Cleaning Conveyor adds another layer of operational efficiency by automatically collecting and redirecting any occasional loose material that may occur during handling.

How it works?

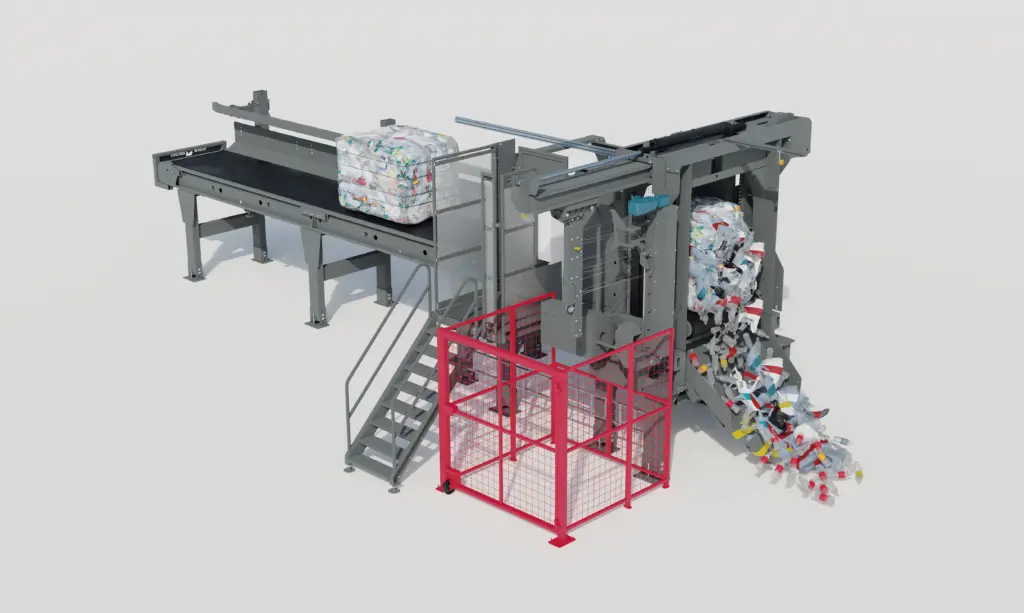

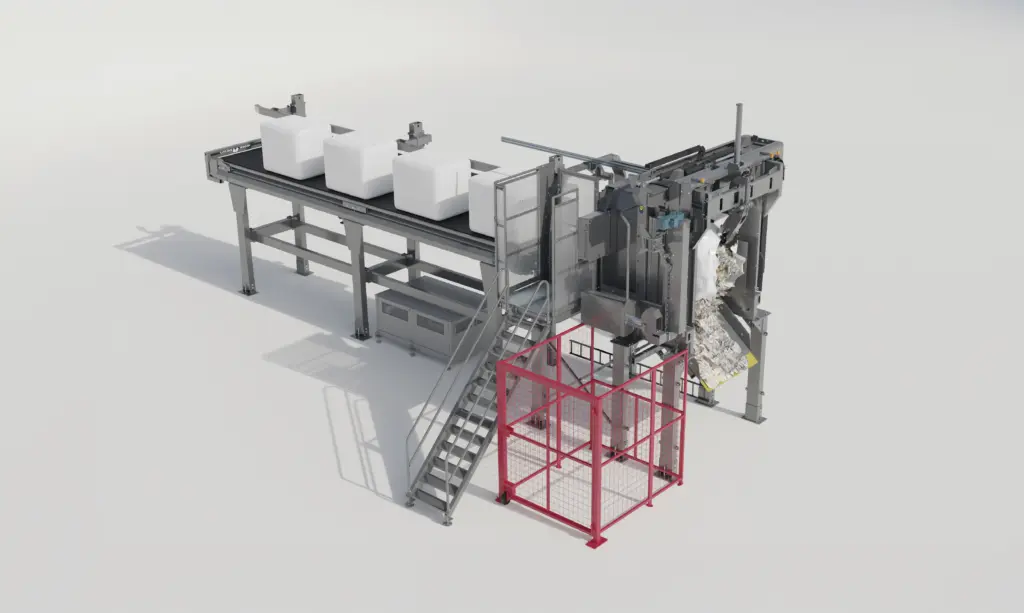

The Cross Wrap Cleaning Conveyor is installed beneath or alongside the wrapping or bale-handling line, it automatically collects and conveys any occasional loose material, such as film trimmings or baled material, that may appear during normal operation.

The system can be configured to direct this material back to the baler, into a separate bin, or to a designated bunker. Fully integrated into the line’s control system, the Cleaning Conveyor operates automatically in sync with production, requiring no additional supervision or manual handling.

Benefits – Why choose Cleaning Conveyors?

Less manual cleaning

Keeps the area under and around the wrapping line clear, reducing the need for time-consuming manual cleanups.

Improved safety

Fewer loose materials on the floor means safer footing and less risk for forklift or operator accidents.

Consistent uptime

Automatic material collection helps prevent stoppages caused by litter buildup or cleaning breaks.

Easy integration

Designed to work seamlessly with Cross Wrap wrapping lines and automation controls.

Better working environment

A cleaner workspace is more pleasant, more efficient, and supports professional maintenance standards.