BALE STACKER

Bale Stacker – Streamline Your Wrapped-Bale Handling Process

Shift to Smart Operations

- Efficiency

- Save space

- Flexibility

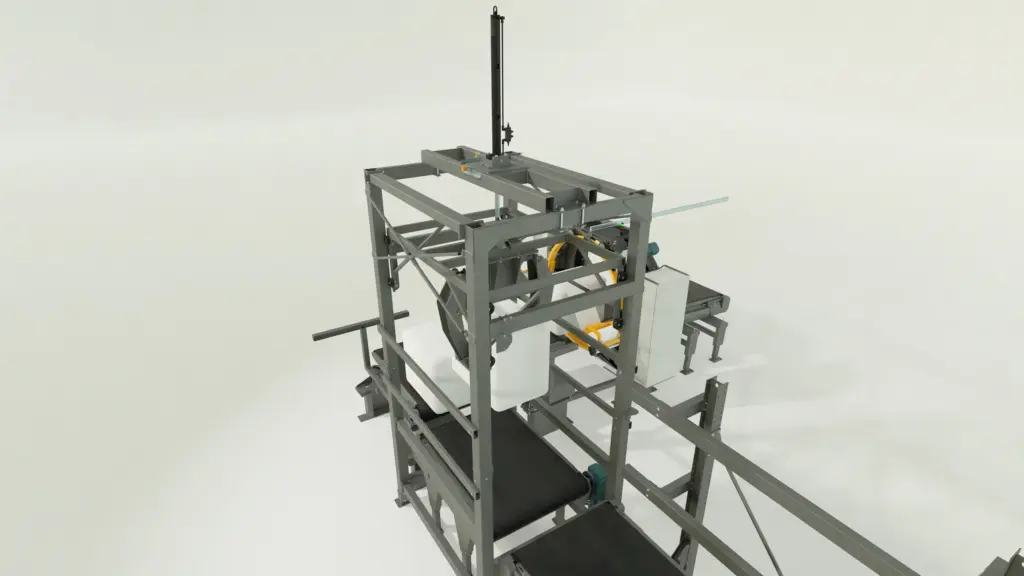

The Bale Stacker is designed to make bale logistics more efficient, safe, and space-saving. Installed after the Bale Wrapper or Direct Bale Wrapper, the Bale Stacker automatically lifts and stacks two wrapped bales, allowing forklift operators to handle them in one move. This smart add-on minimizes forklift traffic, streamlines material flow, and boosts the productivity of your wrapping line.

With its two-mode functionality it offers flexibility to suit different production needs. Its compact design and seamless integration with Cross Wrap’s wrapping systems make it an ideal choice for facilities seeking to optimize handling and maximize efficiency.

How it works?

Bale Stacker is positioned after the wrapper: once the bales are wrapped, the device grabs the first bale and lifts it up so that the conveyor can feed a second bale underneath before the both bales continues to the storage conveyor. Then the forklift can lift both bales at the same time for storage or loading. The operator can select between two modes: stacking mode (two bales lifted) or through mode (normal single bale).

Benefits – Why choose Bale Stacker?

Lift two wrapped bales in one go

Increases efficiency at the end of the operation line. Reduce forklift trips and operator strain.

Compact add-on to your wrapper line

Saves space – Ideal where storage area is limited.

Two-mode operation

Stack or pass-through depending on workflow.

Fits with our Bale Wrappers and Direct Bale Wrappers.

Other value-adding features

Run your operations safe, smooth and efficient.

Conveyors

Cross Wrap’s custom-built conveyors provide reliable material flow between material processing stages. Designed for durability and precision.

Labeling

Print automatically labels to each bale directly at the wrapping line. Improve traceability, support logistics, and integrate with wrapper’s control system.

Weighing

Integrates an automatic scale directly into the line. It records bale or package weights, improving traceability and production monitoring.

Learn how we help your operations to run smoothly with our Life Cycle Services.

Services

We don’t just deliver machines, we deliver long-term reliability, efficiency, and support.

Spare Parts

Use our official spare parts and keep your machines warranty, and lengthen its lifetime.

Upgrades & Modernizations

Focusing on our customer’s needs, Cross Wrap helps you get the most out of your machines.

Ready to find the right solution for your process?

Take contact on our experts.

Why Choose Cross Wrap?

Cross Wrap Oy is a Finnish company specializing in automated bale handling and material flow solutions for the global recycling, waste, and industrial sectors.

With over 650 installations in more than 65 countries, Cross Wrap is known for its innovative bale dewiring, crosswrapping, and opening machines, designed to improve safety, efficiency, and sustainability in material processing.

Cross Wrap was founded in 1994. Today, we are part of Saalasti Group, sharing a commitment to clean technology and durable engineering. Cross Wrap’s mission is to enable cleaner, safer, and more efficient material flows, supporting customers across plastics, paper, board, waste, and fuel processing industries.