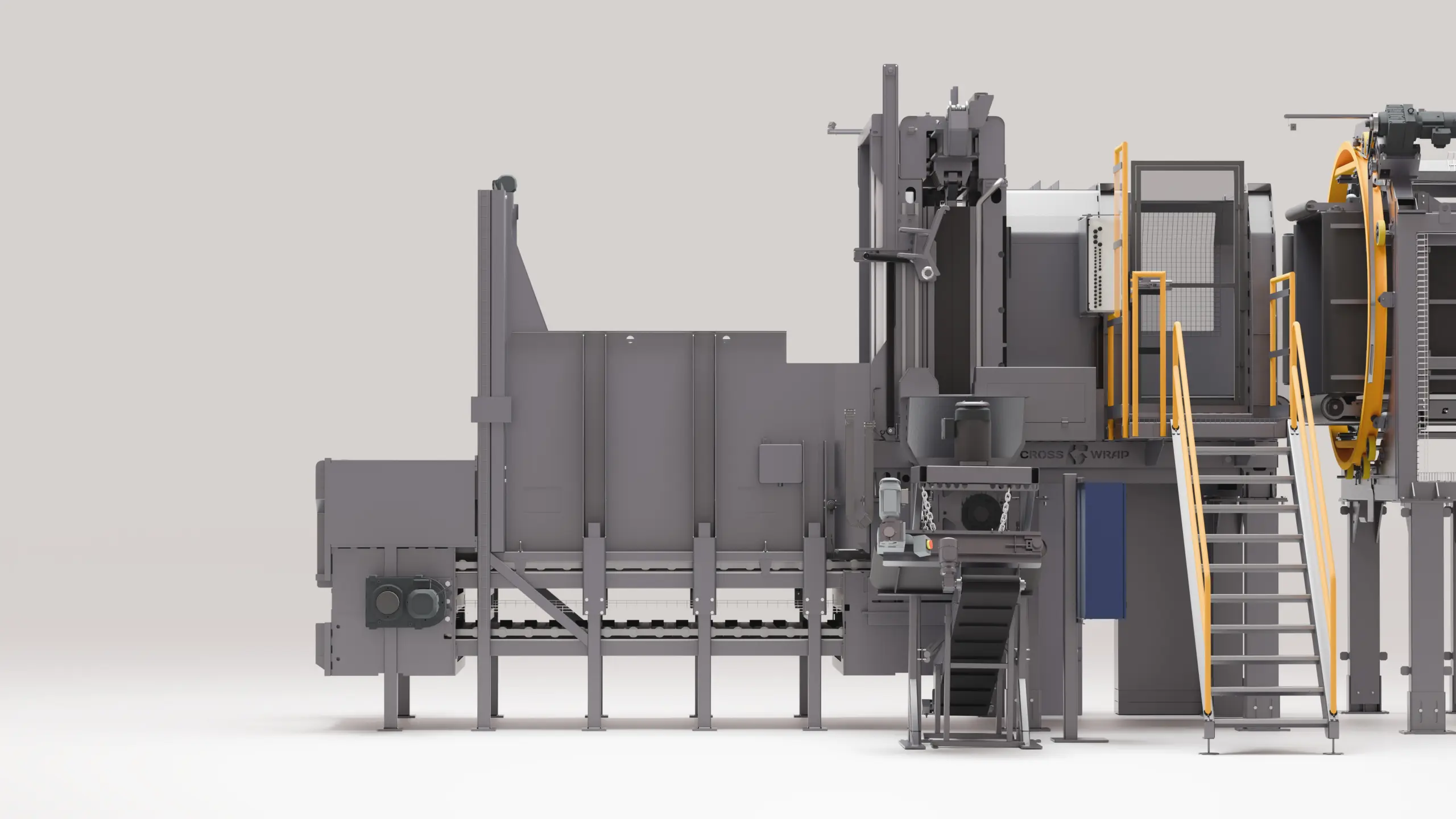

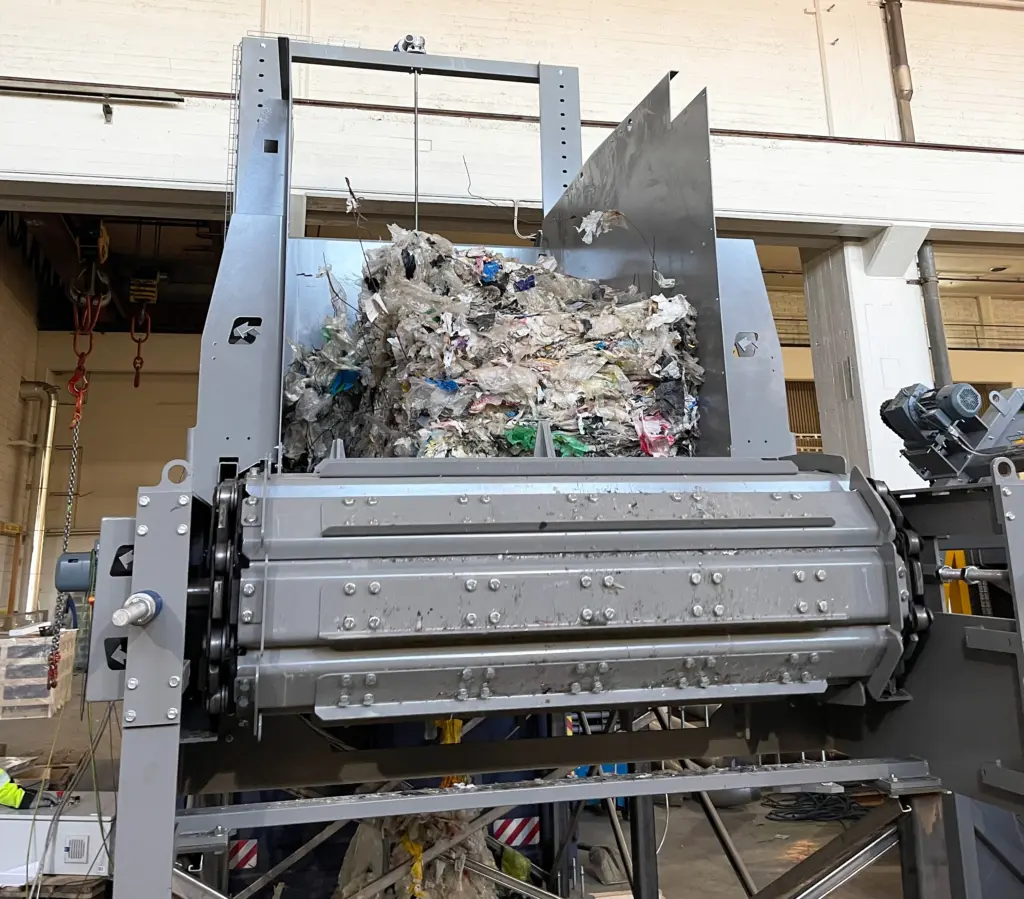

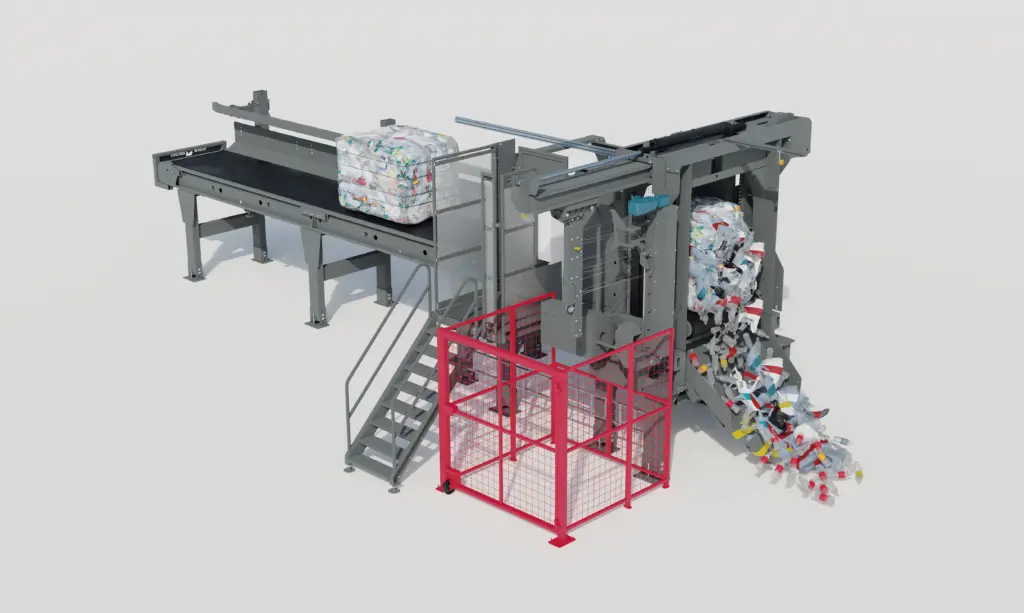

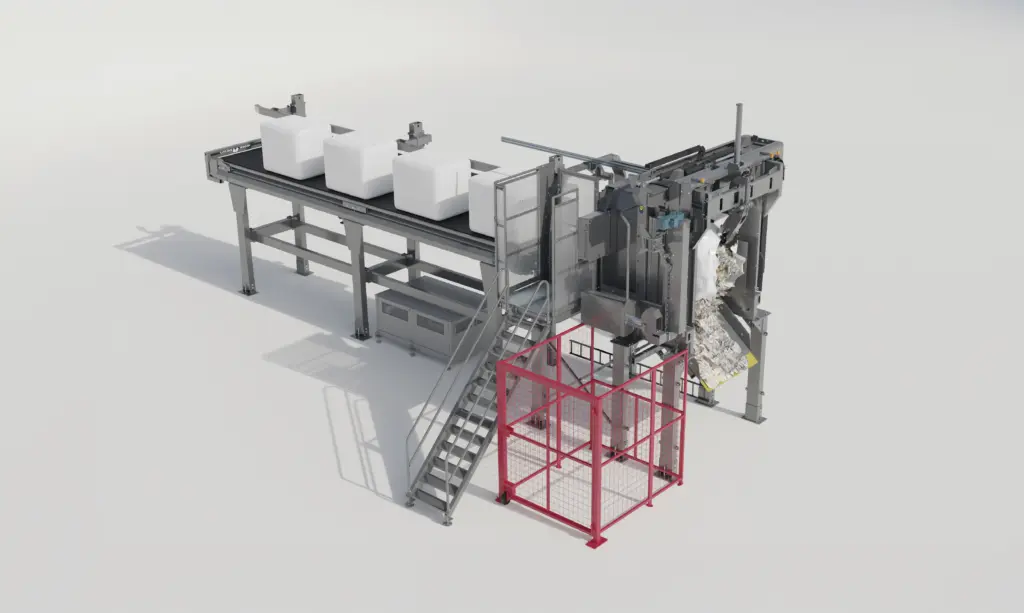

The Bale Slice Breaker is an add-on solution that complements both the Bale Opener and the Dewiring Machine. It breaks tightly compacted slices into smaller pieces, preventing blockages and ensuring a steady material flow. This makes it especially valuable for facilities handling RDF, SRF, plastics, PET bottles and many other materials that make dense bales and may cause stoppages.

How it works?

After dewiring or bale opening, the material slices drop onto the slice breaker conveyor, which breaks the slices against a shear gate. The machine breaks the slices so that PET bottles, for example, stay whole but separate, which is important for a smooth sorting process. This avoids bottlenecks in the line, keeps material feeding consistent, and helps operators maintain higher throughput with less downtime.

Benefits – Why choose Bale Slice Breaker?

More stable process

Ensures a smooth and stable material flow by breaking tight slices immediately after dewiring or bale opening, preventing blockages in your process.

Affordable choice to keep material intact

Offers an affordable solution that keeps material intact – unlike shredders, it preserves items like PET bottles while improving downstream performance.

Works for different materials

Fully adjustable shear gate and conveyor speed make the system adaptable for a wide range of materials and capacities.

Reduce downtime and helps maximize production efficiency

Designed for easy operation alongside the bale opener or dewiring machine, it’s controlled from the same panel and supports a single contact for maintenance.