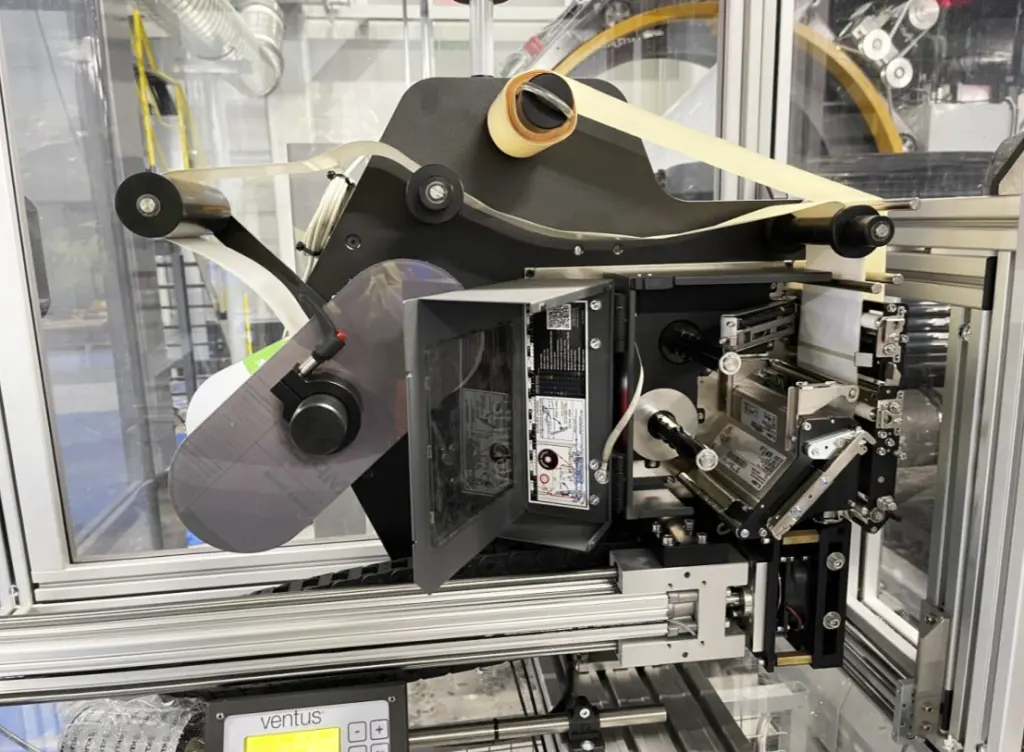

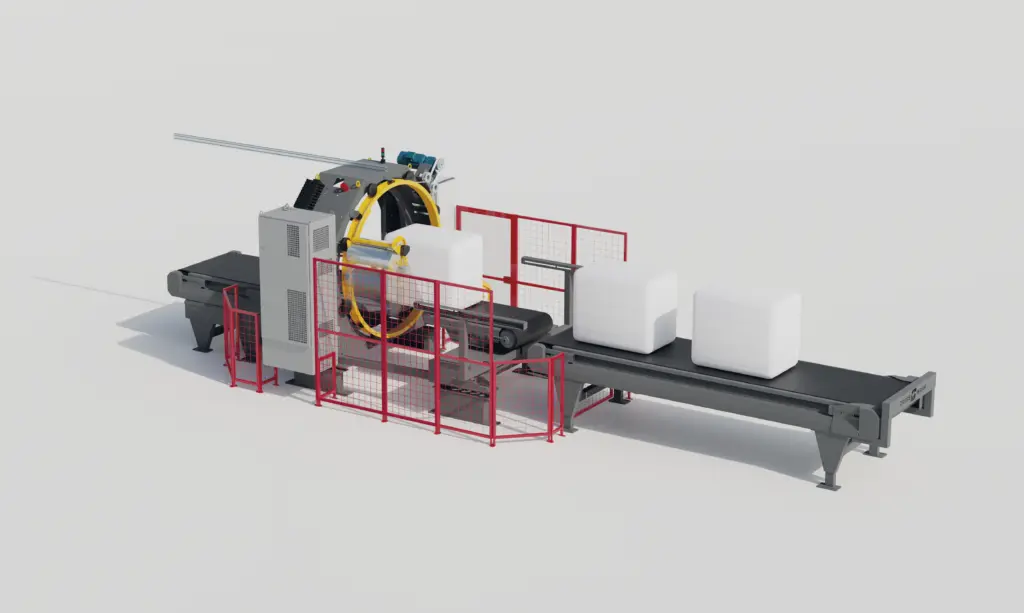

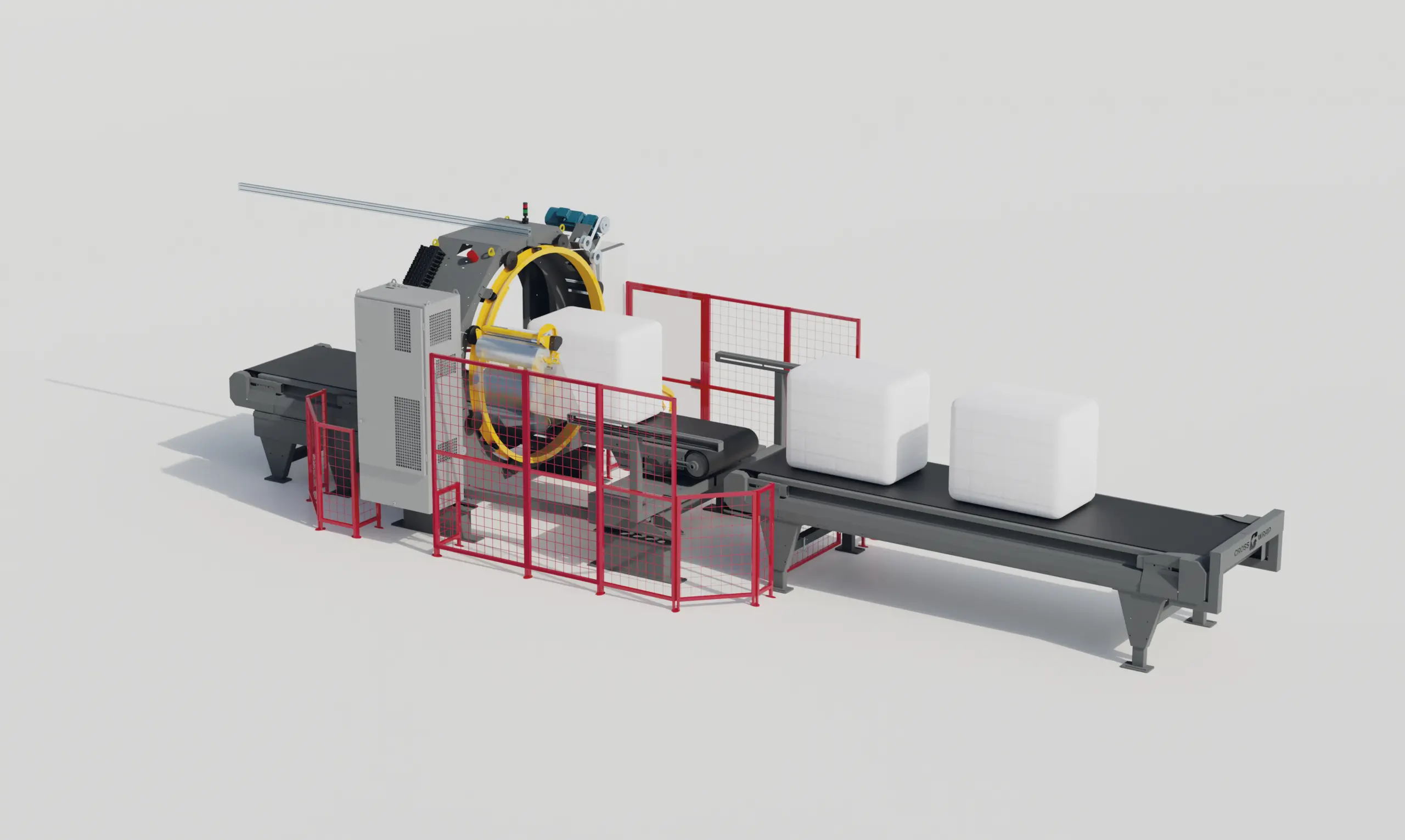

The Cross Wrap Labeling Unit offers an efficient and automated way to identify every wrapped bale directly at the wrapping line. Fully integrated into the wrapper’s control system, it enables precise, consistent labeling that supports traceability, storage, and logistics, all without slowing down production.

Designed for flexibility and ease of use, the Labeling Unit can operate automatically or manually, with label layouts customizable to your specific process and data needs.

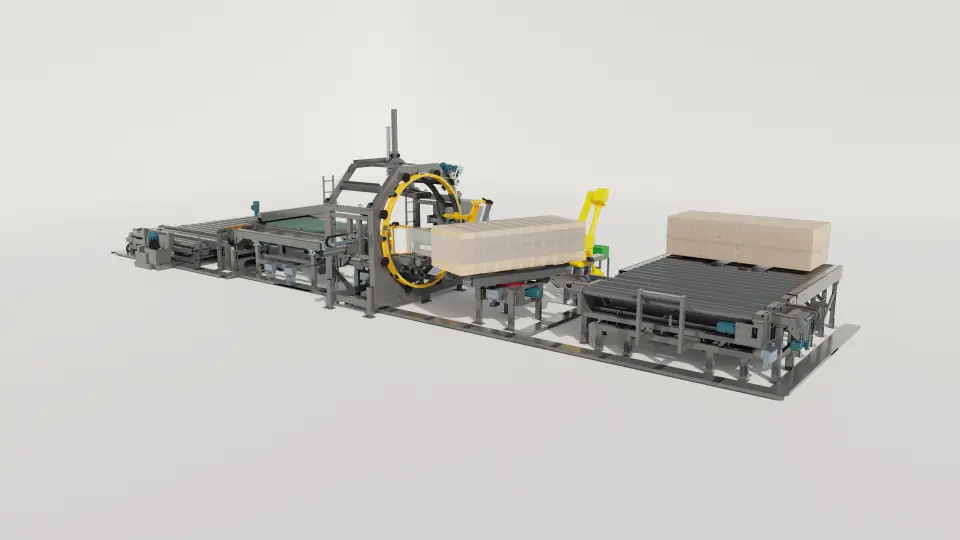

For industrial board packaging lines, we offer high-quality labeling robots that provide accurate product information and strengthen your company image branding possibilities.

How it works?

The Labeling Unit connects to the machine’s control system via Profinet and works seamlessly with the machine’s automation.

- When the machine operates in automatic mode, labels are printed automatically for each bale or package.

- Labels can also be printed manually from the operator panel when needed.

Wrapper labeling can be performed using heat writing, which eliminates the need for ink rolls, or through heat transfer printing, where ink is transferred to paper from an ink roll.

Labels can include a wide range of information, such as:

- Barcodes or QR codes for logistics and traceability

- Bale number and weight

- Material type

- Running numbering or production batch

- Date and time

- Manufacturer contact details

Benefits – Why choose automated Labeling?

Integrated operation

Connected directly to the machine’s control system for smooth and automatic labeling.

Flexible printing method in wrappers

Choose between heat writing or heat transfer printing based on your preferences.

Automatic or manual control

Prints automatically during auto-mode or manually from the operator panel.

Customizable label design

Modify fields and layout easily.

Improved traceability

Barcodes and unique bale or package IDs support efficient inventory and transport management.

Low maintenance costs

Heat writing removes the need for ink rolls, reducing consumable costs and downtime.